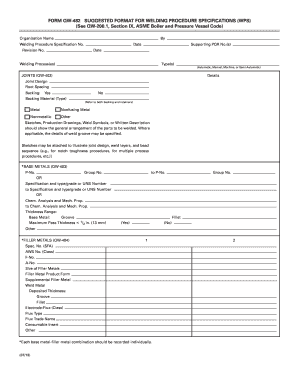

Get the free welding procedure specification template form

Get, Create, Make and Sign

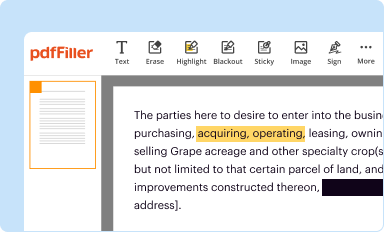

Editing welding procedure specification template online

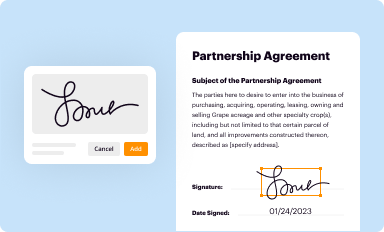

How to fill out welding procedure specification template

How to fill out a welding procedure?

Who needs a welding procedure?

Video instructions and help with filling out and completing welding procedure specification template

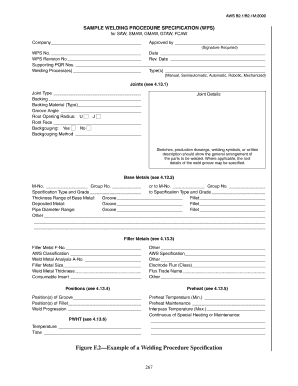

Instructions and Help about sample welding procedure specification form

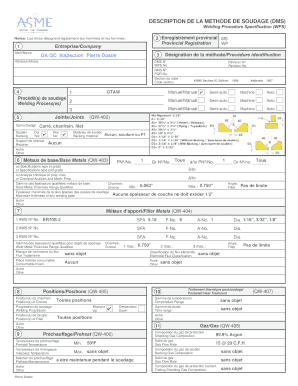

All right what I'm going to do is three videos because there are three things that go into welding procedures the first video will be on a welder procedure specification or WPS second video will be on a procedure qualification record the thirdly a welder qualification tax record these are all things that are associated with getting certified in welding the first the WPS is basically a proposition for a process that needs to be proven good the procedure qualification record is what you do to prove that the WPS is good and then the welder qualification test records are when you certify the welders to the PQR they become a certified welder, so we'll be three videos one WPS one on a PQR and one own TRE this being the first video a three video series on welder certification the first one it's going to be on welding procedure specifications like I said before it's like a proposition for a process that's going to be used at a company this is all hypothetical, so there's not a real company here but the first thing you're going to do I want when you write a WPS is going through general info it's going to ask you your company name um, so we're just going to make it up and say that it's company an authorized by it's going to be some kind of Foreman or manager or owner or something along them lines, so we're just going to say by some kind of boss the date December 9th 2014 revision I always start with zero and if you do a revision it goes to zero one zero two consecutively it's going to be the same date by and that would be your CGI and certified welding inspector which would be me what we're going to do is we're going to do a stick weld, and we're going to pretend stick weld, so it's going to be the only process we're going to do here is Sawed and you never leave an in these blank they always have to have something in them so if there's otherwise it leaves a doubt in the mind of whoever was reading it was that left out or was it purposely left blank, so I always put an ain't applicable that's if you had a pre-qualified junk joint sporting PQR numbers there shouldn't be any if you're just starting out so all those are going to be n/a so once you do one you just copy and paste it PQ R I write that it's going to be the next video I do it's the normal sequence you would go into if you were doing this it's a manual process your base metal specs we're just going to assume they're going to be using an 36 steel it's very common we don't really have a type of grade, and we're going to go with a vertical lap like I said let's just say it's a three-eighths groove thickness point three seven five to another point three seven five that's going to be in inches Phillips there is none, so again you're going to do your n A's diameter pipe we're not doing pipe, so it's going to be n A's again specification I believe is a five point nine one we're using silver that an eight of us classification we're going to say this is her 7018 sewing one we're going to use and our theory...

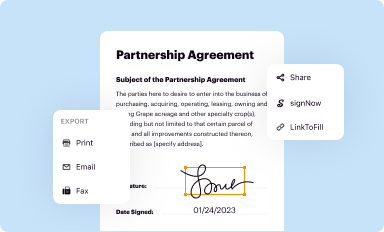

Fill welding specification procedure : Try Risk Free

Our user reviews speak for themselves

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

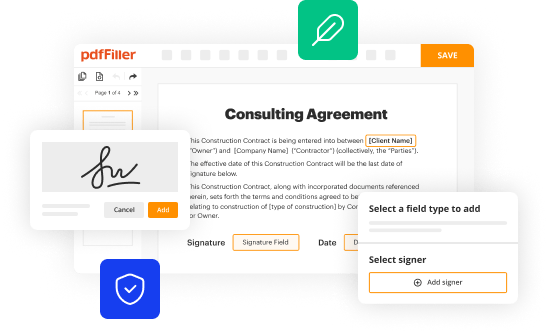

Fill out your welding procedure specification template online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.